Introduction

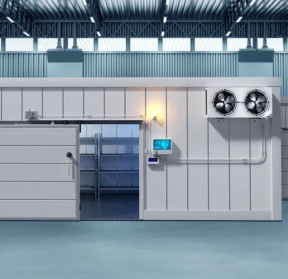

Air1 Water operates air-to-water production units that must function reliably under varying environmental conditions. Exposure to low temperatures posed a risk of freezing, potentially disrupting operations and damaging critical equipment. To mitigate these risks, Air1 Water partnered with Covansys Technologies to design and implement an intelligent freeze protection automation system. The solution continuously monitors environmental conditions and automates protective responses to ensure the uninterrupted operation of air-to-water production units.

Challenges in Freeze Risk and Operational Continuity

Key Issues Impacting System Reliability

Stevin Rock faced several inventory management challenges across its silo-based material storage:

Optimizing Operations with Covansys’ Automation Solution

Covansys implemented a freeze protection control system designed to proactively safeguard equipment and maintain stable operations.

Deployed sensors to continuously monitor ambient conditions.

Activated protection mechanisms based on predefined thresholds.

Used automation logic to respond instantly to freezing risks.

Enabled centralized visibility of system status and alerts.

Minimized dependency on manual monitoring and actions.

Designed to support additional units and future expansion.

Operational Reliability and System Protection for Air1 Water

Covansys’ freeze protection automation solution provided Air1 Water with an intelligent and reliable system to monitor temperature conditions and protect air-to-water production units. The solution helped reduce freeze-related risks, improve system reliability, and ensure uninterrupted operations during low-temperature conditions.

Reduction in freeze-related operational risks

Improvement in system reliability and uptime

Reduction in manual monitoring and intervention

Faster response to temperature threshold breaches

Conclusion

By implementing an intelligent freeze protection automation system, Covansys helped Air1 Water safeguard its air-to-water production units against freezing risks. The solution ensured reliable operation, minimized downtime, and provided proactive protection through real-time monitoring and automated controls.

Ready to Improve Inventory Visibility?

If Air1 Water can rely on Covansys for intelligent freeze protection automation, your operations can too. Let us design a customized automation solution to safeguard your critical systems and ensure uninterrupted performance.